Duo Plus InkJet

Duo Plus InkJet

Maximum performance and reliability in the most demanding conditions Duo printer is IP66-certified, and this is connected to the corresponding class-leading performance and compatibility, unique closed completely tight into the housing. Both have created the best commercially available printer very demanding conditions. Sold in a duo with two versions of the jet stream, which meet all applications, which require a completely closed tightly printer.

A series of printers have a unique body and cooling system to protect the printer from dust in the air, moisture and other impurities from. The printer works properly even with the high-temperature environment.

GREAT PERFORMANCE

- IP66-protected stainless steel (quality 316) housing

- The factory compressed air cortex cooling

- Operationally, there has been no compromise made

HIGH RELIABILITY

- The patented print head nozzle closing system and full-automatic washing guarantee a certain starting day to day and week to week,

- Based on the Domino A series, which includes the well-known quality standard Domino functions

- Reliability – high-volume sealed ink system, sealed nozzles, easy replacement of the ink

- Predictability – stable features, reliable technology

COMPATIBILITY AND FLEXIBILITY

- Ethernet interface and a USB port as standard

- All raster and print formats, including the A Plus Duo models of double lines and line spacing reduced raster

- Built-in web server and message signals (user-determined)

APPLICATIONS

- Soft drink / dairy – very wet air and high humidity or a large concentration of sugar syrup

- Food – solids, dusts, vapors and / or a high percentage of humidity

- Metal production – oil mist or metal particles and -tolm

- Building materials – cement or dust particles

- Chemicals – plastics, resins, fibers, chemicals and solvents

- Paper and cardboard – dust

DOMINO XS

The A-Series XS is specifically designed to meet the demands of customers in high-speed industries such as canning, Beverage and Cable and Wire . The specifically developed variant runs at speeds up to 30% faster than the rest of the A-Series range. For outstanding clarity and contrast on dark surfaces such as cable and wire, dark bottles and plastics, the A-Series XS can print Opaque codes at the speeds required.

Robust and Reliable

The A-Series XS is not only fast, it is also supremely reliable at producing consistent levels of print quality and reliable performance during round the clock production. The superb “start-stop” performance ensures that the A-Series XS operates as an integrated part of the production process, thereby maintaining production line efficiency.

Easy to Maintain

As with all A-Series, manual printhead cleaning is a preventative maintenance procedure rather than the daily routine. The fully automated start up and shut down system using Domino’s nozzle sealing feature means that production and coding can start when you want, without the delays associated with other systems.

Fluids

The A-Series XS supports a range of advanced performance fluids to suit your application. Ideal for the bottled drinks industry, Domino’s “wet bottling” ink has excellent adhesive properties on wet surfaces – even at high speeds – and will not rub off under refrigeration.

DOMINO Opaque

Exceptional print quality and brightness on small areas and components

-

Clarity and contrast on dark uneven surfaces

-

Highly visible coding where type identification is crucial

-

Ideal for product tractability

-

Automatically tests and maintains inks viscosity when printer is idle to ensure perfect coding

Bright Clear Coding

Suitable for use in almost any industry where dark surfaces need to be coded or identified, the A-Series plus Opaque effortlessly produces high visibility, high quality codes. Available with a range of specially designed, Advanced Performance fluids including white inks with outstanding brightness to provide high contrast on a wide range of dark surfaces.

Consistent Quality

The A-Series plus Opaque provides the same dependable performance, reliability, and code quality that you have come to expect from the Domino A-Series plus range. To give optimum print quality and brightness, Opaque fluids need to be kept in constant motion keeping the pigments evenly distributed. This happens naturally when the printer is being used; but, when production stops, Domino’s special WakeUp software takes over and maintains the ink in perfect condition ready for the next production run.

Ease of Use

Designed with the operator in mind, the A-Series Opaque is easy to use. With its big screen, big button interface, and easy to handle fluids, the A-Series Opaque makes day to day operation quick, efficient and virtually error free.

-

Simple Start Up and Shut Down

-

Simple message setup and storage for quick product changeovers

-

Easy to maintain

Message setup is simple with the A-Series Opaque. Hot keys make frequently used functions easily accessible. Codes can also be prepared and stored to save time during production changeover.

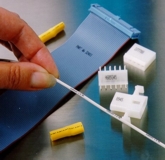

DOMINO Pinpoint

The Domino Pinpoint printer delivers print as small as 0.8mm in height and is ideal for applications such as Cable and Wire marking , Electronics , Pharmaceuticals , automotive parts and Cosmetics and Personal Care where codes must be both discreet and high quality.

High-Quality and Legibility

-

Modular design and heated head technology ensure that code quality remains constant from start of production to line shutdown

-

Prints single line at up to 178 meters (580 feet) per minute where character spacing is 26 characters per inch, or up to 308 meters (1010 feet) per minute at 15 characters per inch

-

High accuracy of dot placement makes Pinpoint ideal for Data Matrix Coding

-

Capable of small legible print on small objects / spaces

Easy to Maintain

As with all A-Series, manual printhead cleaning is a preventative maintenance procedure rather than the daily routine. The fully automated start up and shut down system using Domino’s nozzle sealing feature, means that production and coding can start when you want, without the delays associated with other systems.